The Story of the Army Green Machines

A bit of history first. Burroughs released the Class 8 Portable Adding Machine in 1925. This machine did not have subtraction capability, but was very popular none the less. In 1926, Burroughs released the Class 9 Portable Adding machine, which included subtract capability. Both of these models could be purchased as hand operated or with an internal motor.

The Burroughs portable adding machine continued to be produced until about the early 1970’s. One of the most popular business machines ever introduced, the machine went through many changes during the years.

One of the obvious things that changed over the years was the outside color of the machine. The early machines were all painted black, which was an industry standard of the time. In the late 1940’s, Burroughs moved to a brown color and later made a number of other color changes.

That brings us to the topic of this article. In the early 1940’s, as the country moved to increased war time production, Burroughs began to support the war effort. As early as 1941, Burroughs began producing Class 8 and 9 machines with an appropriate wartime color that we would call “Army green”. Examples of these “green machines” can be found in production up into 1945. At that time Burroughs moved back to the traditional black color.

Many of these machines were sold to the military, but they were also available to businesses as well. While these machines are somewhat scarce today, examples can be found for sale as antiques. Some examples include markings or decal/stickers related to the military units that they belonged to.

The “green machines” were almost exactly the same construction as the normal commercial Class 8 and 9 machines, however, there were some interesting changes implemented for the war environment. Not all of these machines included all of the changes, and some had no changes from the traditional machines other than this new green color.

Some of the changes seem to have been implemented to protect the machine from field conditions, while other changes were made to protect the environment around the machine. In addition, some changes were made to support a more transit environment.

These are the changes that are seen most often:

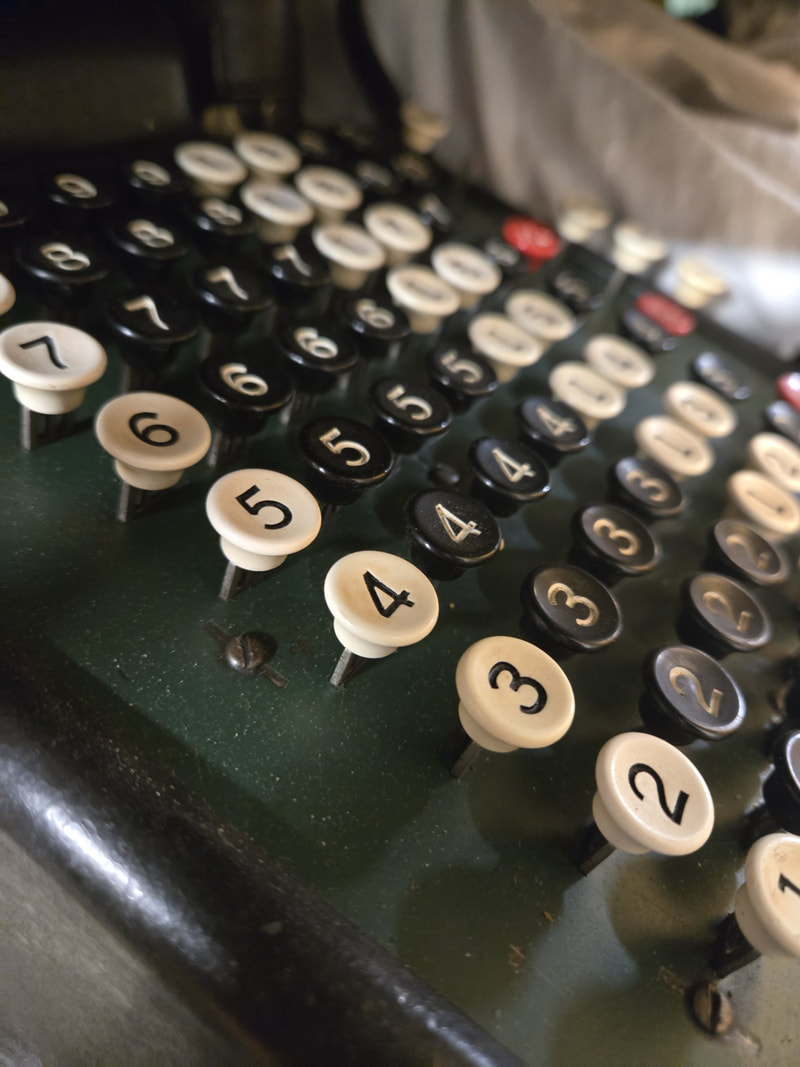

The keyboard was fitted with covers in each column and the keytops were redesigned with a broad shank that fitted close to the cover. (See pictures below) This was done to reduce the amount of dirt or dust that would be able to enter the keyboard mechanism around the keystems. This change was not seen on machines after wartime production ended.

As an option, some motors were fitted with spark arrestors to allow the machine to be used in explosive environments. This change continued to be available, after the war years, as an option to commercial customers with that specific need.

Another change was a bracket on the rear of the machine for winding the machine cord up and also for storing the handle (or machine crank) when transporting the machine. Motorized machines often came with a handle as a back-up where electricity was not available. The right side of the machine had a sliding cover for the handle hole when the handle was removed for storage. This would prevent dirt from entering the machine when the handle was stored.

The story of the Army green Class 8 and 9 machines is only one part of the Burroughs wartime production. Another very notable effort was the creation and production of the Norden Bomb Sight, critical to the war effort. In addition, a Burroughs plant in the Detroit area was converted to Army tank production.

Like so many businesses during World War II, Burroughs stepped up to the challenge to support the war effort.

The Burroughs portable adding machine continued to be produced until about the early 1970’s. One of the most popular business machines ever introduced, the machine went through many changes during the years.

One of the obvious things that changed over the years was the outside color of the machine. The early machines were all painted black, which was an industry standard of the time. In the late 1940’s, Burroughs moved to a brown color and later made a number of other color changes.

That brings us to the topic of this article. In the early 1940’s, as the country moved to increased war time production, Burroughs began to support the war effort. As early as 1941, Burroughs began producing Class 8 and 9 machines with an appropriate wartime color that we would call “Army green”. Examples of these “green machines” can be found in production up into 1945. At that time Burroughs moved back to the traditional black color.

Many of these machines were sold to the military, but they were also available to businesses as well. While these machines are somewhat scarce today, examples can be found for sale as antiques. Some examples include markings or decal/stickers related to the military units that they belonged to.

The “green machines” were almost exactly the same construction as the normal commercial Class 8 and 9 machines, however, there were some interesting changes implemented for the war environment. Not all of these machines included all of the changes, and some had no changes from the traditional machines other than this new green color.

Some of the changes seem to have been implemented to protect the machine from field conditions, while other changes were made to protect the environment around the machine. In addition, some changes were made to support a more transit environment.

These are the changes that are seen most often:

The keyboard was fitted with covers in each column and the keytops were redesigned with a broad shank that fitted close to the cover. (See pictures below) This was done to reduce the amount of dirt or dust that would be able to enter the keyboard mechanism around the keystems. This change was not seen on machines after wartime production ended.

As an option, some motors were fitted with spark arrestors to allow the machine to be used in explosive environments. This change continued to be available, after the war years, as an option to commercial customers with that specific need.

Another change was a bracket on the rear of the machine for winding the machine cord up and also for storing the handle (or machine crank) when transporting the machine. Motorized machines often came with a handle as a back-up where electricity was not available. The right side of the machine had a sliding cover for the handle hole when the handle was removed for storage. This would prevent dirt from entering the machine when the handle was stored.

The story of the Army green Class 8 and 9 machines is only one part of the Burroughs wartime production. Another very notable effort was the creation and production of the Norden Bomb Sight, critical to the war effort. In addition, a Burroughs plant in the Detroit area was converted to Army tank production.

Like so many businesses during World War II, Burroughs stepped up to the challenge to support the war effort.

Standard keyboard keystems

Standard keyboard keystems