Product Servicing Information

There are several areas of servicing listed below including:

High Keyboard (Class 1, 2, & 6) Machine Informational Videos

1 - Introduction and Getting Basic Add and Subtract Running

2 - Carriage Work and Machine Demos

3 - Cleaning the Keyboard Felt

4 - Cleaning the Machine Up

Class 1 Operation

Case Key Usage

Class 3 Ribbon Installation

Class 8 & 9 Case Removal Procedure

Finding Cash in an Old Cash Machine

Class 8 & 9 Motor Removal Procedures

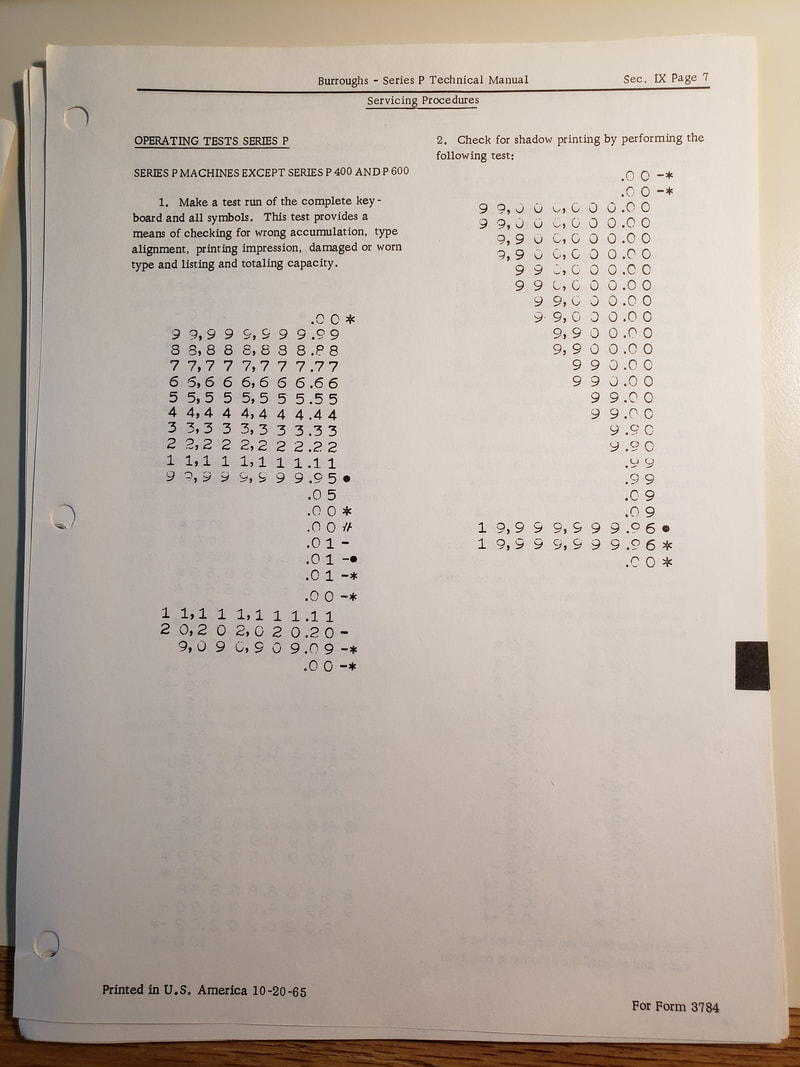

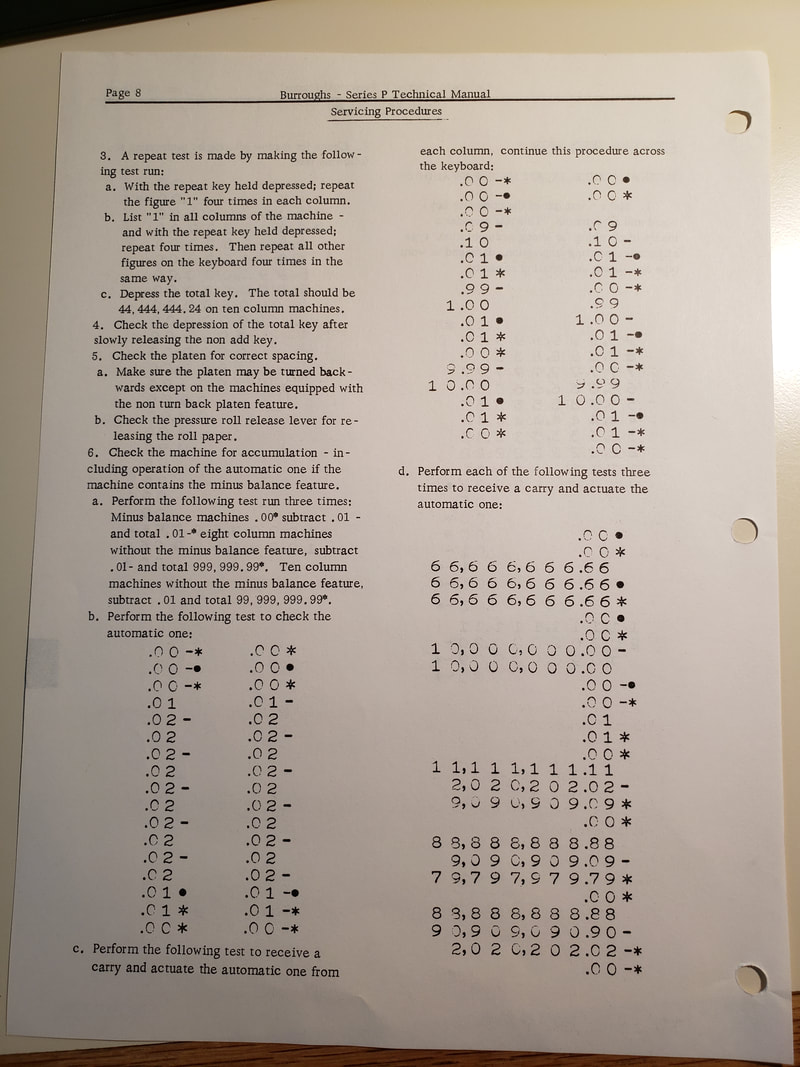

Class 8, 9, 10 and Series P Operating Tests

Removing the Case on an Early Class 1

Getting Replacement Burroughs Decals

Oil Bottles Available

High Keyboard (Class 1, 2, & 6) Machine Informational Videos

1 - Introduction and Getting Basic Add and Subtract Running

2 - Carriage Work and Machine Demos

3 - Cleaning the Keyboard Felt

4 - Cleaning the Machine Up

Class 1 Operation

Case Key Usage

Class 3 Ribbon Installation

Class 8 & 9 Case Removal Procedure

Finding Cash in an Old Cash Machine

Class 8 & 9 Motor Removal Procedures

Class 8, 9, 10 and Series P Operating Tests

Removing the Case on an Early Class 1

Getting Replacement Burroughs Decals

Oil Bottles Available

High Keyboard (Class 1, 2, & 6) Machine Informational Videos

These YouTube videos were created and provided by Ed Rupp. Ed has a YouTube channel called "The ID of Ed". The URL for Ed's channel is: https://www.youtube.com/channel/UCtBGrxdGsbbyz9oZk8mKJbA/videos

Thanks to Ed for providing this interesting and informative information.

1 - Introduction and Getting Basic Add and Subtract Running

https://www.youtube.com/watch?v=bTGWs-XCMfw

This video is a first of a series covering a Burroughs High-Keyboard Bookkeeping machine. In this episode I introduce the machine and explore it's condition and go from knowing very little about the machine to learning how cool and remarkable the machine is.

2 - Carriage Work and Machine Demos

https://www.youtube.com/watch?v=_4acYyAQeAI

This is the second video on the Burroughs High-Keyboard Bookkeeping machine. In this episode I explore the carriage and print head system. I do some lubrication and repairs. Most of all sort out and understand the machine some more. This adding machine is quite a bit more complex and has a lot more features than what you would expect from a classic adding machine.

3 - Cleaning the Keyboard Felt

https://www.youtube.com/watch?v=7KPfhu3rgdo

This video is part three, working on my 1917 Burroughs High-Keyboard Bookkeeping machine. In this episode I work on cleaning the keyboard of the machine. The machine has this very nice green felt covering the top surface, below the key buttons. To clean between the buttons and ley stems necessitated the design and 3D printing of small cleaning wands.

4 - Cleaning the Machine Up

https://www.youtube.com/watch?v=wOIrrO3ujX4

This video is part four, working on the Burroughs High-Keyboard Bookkeeping machine. In this episode I work on cleaning the case with the marvelous windows and overall the outside of the machine. I go over some cleaning methods and cleaning agents.

These YouTube videos were created and provided by Ed Rupp. Ed has a YouTube channel called "The ID of Ed". The URL for Ed's channel is: https://www.youtube.com/channel/UCtBGrxdGsbbyz9oZk8mKJbA/videos

Thanks to Ed for providing this interesting and informative information.

1 - Introduction and Getting Basic Add and Subtract Running

https://www.youtube.com/watch?v=bTGWs-XCMfw

This video is a first of a series covering a Burroughs High-Keyboard Bookkeeping machine. In this episode I introduce the machine and explore it's condition and go from knowing very little about the machine to learning how cool and remarkable the machine is.

2 - Carriage Work and Machine Demos

https://www.youtube.com/watch?v=_4acYyAQeAI

This is the second video on the Burroughs High-Keyboard Bookkeeping machine. In this episode I explore the carriage and print head system. I do some lubrication and repairs. Most of all sort out and understand the machine some more. This adding machine is quite a bit more complex and has a lot more features than what you would expect from a classic adding machine.

3 - Cleaning the Keyboard Felt

https://www.youtube.com/watch?v=7KPfhu3rgdo

This video is part three, working on my 1917 Burroughs High-Keyboard Bookkeeping machine. In this episode I work on cleaning the keyboard of the machine. The machine has this very nice green felt covering the top surface, below the key buttons. To clean between the buttons and ley stems necessitated the design and 3D printing of small cleaning wands.

4 - Cleaning the Machine Up

https://www.youtube.com/watch?v=wOIrrO3ujX4

This video is part four, working on the Burroughs High-Keyboard Bookkeeping machine. In this episode I work on cleaning the case with the marvelous windows and overall the outside of the machine. I go over some cleaning methods and cleaning agents.

Class 1 Operation

The slideshow below are pages from a very rare 1904 book called "Symbol Book and Instructions for Operating, Oiling, and Adjusting the Burroughs Adding Machine". The book was published by the American Arithmometer Company - 21st & Wash Streets, St. Louis, MO., USA.

The slideshow below are pages from a very rare 1904 book called "Symbol Book and Instructions for Operating, Oiling, and Adjusting the Burroughs Adding Machine". The book was published by the American Arithmometer Company - 21st & Wash Streets, St. Louis, MO., USA.

All About Case Keys

Burroughs Class 1, 2, 3, 6 Base Key Instructions

Your case key will only work on Burroughs Class 1, 2, 3, 6 style machines. Please remember that the key is only to assist in removing the upper case of the machine to allow servicing. The key does not have anything to do with the operation of the machine.

Once all other parts of the machine that would prevent the case from being lifted off have been removed, the case key can be used to unlatch the upper case from the lower case. Other parts might include screws on the back of the machine, the paper and ribbon printing area, and some control keys on the keyboard (these are always held on by little screws). Do not attempt to remove other keytops.

The latch only has to move a very short amount, maybe 1/8th of a turn, to allow the upper case to be lifted off. The latch is under spring tension, so the key must be held in the turned position while the case is lifted up.

Insert the key all the way and turn the key in a counter clockwise direction. The key will meet some resistance when it is fully engaged. At that point, continue turning the key slightly until it cannot be turned further. The latch will be released as long as the key is held in this position. Once the case is lifted off, it will be easy to see how the latch works.

On some machines, you may find that the spring in the latch has been removed or disabled. This was done by the servicing technician as the keys became scarcer.

Burroughs Class 1, 2, 3, 6 Base Key Instructions

Your case key will only work on Burroughs Class 1, 2, 3, 6 style machines. Please remember that the key is only to assist in removing the upper case of the machine to allow servicing. The key does not have anything to do with the operation of the machine.

Once all other parts of the machine that would prevent the case from being lifted off have been removed, the case key can be used to unlatch the upper case from the lower case. Other parts might include screws on the back of the machine, the paper and ribbon printing area, and some control keys on the keyboard (these are always held on by little screws). Do not attempt to remove other keytops.

The latch only has to move a very short amount, maybe 1/8th of a turn, to allow the upper case to be lifted off. The latch is under spring tension, so the key must be held in the turned position while the case is lifted up.

Insert the key all the way and turn the key in a counter clockwise direction. The key will meet some resistance when it is fully engaged. At that point, continue turning the key slightly until it cannot be turned further. The latch will be released as long as the key is held in this position. Once the case is lifted off, it will be easy to see how the latch works.

On some machines, you may find that the spring in the latch has been removed or disabled. This was done by the servicing technician as the keys became scarcer.

Burroughs Adding Machines - Ribbon Installation - Class 3

To Remove the Old Ribbon

Unscrew the two small thumb screws at the top of each ribbon cover. Lift off the covers and place them on the table in the correct orientation that they came off the machine. Don’t mix them as they need to go back on the correct sides.

Take a picture of the ribbon area so you record how the ribbon goes around the guides.

Lift off the ribbon by grasping both spools and pulling upward.

If the replacement ribbon has a two-spool ribbon, then the old ribbon can be discarded with the spools. (Go to “To Put on a New Ribbon”)

If the replacement ribbon is a single spool, you will need to save one of the spools you are removing. Unwind the ribbon from one or both spools. Discard ribbon after pulling the cloth off the arrow shaped hook in the center of the spool. (Go to “Attach New Ribbon to the Second Spool”)

Attach New Ribbon to the Second Spool

Unwind about 6 inches of the new ribbon from the single spool it is wound on. New ribbons may be messy so take care not to get ink on furniture, etc.

Pick up the empty spool from the old ribbon and the end of the new ribbon. Feed the end of the ribbon through the center of the old spool and hold the end of the ribbon tight against the arrow shaped point in the center of the spool. You will likely need a small screwdriver or similar object to push the end of the ribbon through the holes. Pull hard on the other end of the ribbon to force the point through the cloth.

Once the end of the new ribbon is secure on the arrow shaped point, start winding the new ribbon from the new spool to the old spool. The ribbon must be wound on the spools correctly in order to feed correctly. If you put the ribbon spools next to each other on the table with the ribbon unwinding toward you from both spools, you should see that the spool on the left is unwinding counter clockwise and the spool on the right would unwind clockwise.

To Put on a New Ribbon

Installing the ribbon is a simple task. Hold one spool in each hand and work the ribbon down in front of the paper and behind both guides. Then place the ribbon spools down on the ribbon posts. Turn one of the spools to take up any slack. Now reinstall the ribbon covers so that the notch in the top where the post shows through the cover is turned so the slot matched the top of the post. The covers will not turn if the alignment is not correct. Put the thumb screws back on each cover. You are done!

To Remove the Old Ribbon

Unscrew the two small thumb screws at the top of each ribbon cover. Lift off the covers and place them on the table in the correct orientation that they came off the machine. Don’t mix them as they need to go back on the correct sides.

Take a picture of the ribbon area so you record how the ribbon goes around the guides.

Lift off the ribbon by grasping both spools and pulling upward.

If the replacement ribbon has a two-spool ribbon, then the old ribbon can be discarded with the spools. (Go to “To Put on a New Ribbon”)

If the replacement ribbon is a single spool, you will need to save one of the spools you are removing. Unwind the ribbon from one or both spools. Discard ribbon after pulling the cloth off the arrow shaped hook in the center of the spool. (Go to “Attach New Ribbon to the Second Spool”)

Attach New Ribbon to the Second Spool

Unwind about 6 inches of the new ribbon from the single spool it is wound on. New ribbons may be messy so take care not to get ink on furniture, etc.

Pick up the empty spool from the old ribbon and the end of the new ribbon. Feed the end of the ribbon through the center of the old spool and hold the end of the ribbon tight against the arrow shaped point in the center of the spool. You will likely need a small screwdriver or similar object to push the end of the ribbon through the holes. Pull hard on the other end of the ribbon to force the point through the cloth.

Once the end of the new ribbon is secure on the arrow shaped point, start winding the new ribbon from the new spool to the old spool. The ribbon must be wound on the spools correctly in order to feed correctly. If you put the ribbon spools next to each other on the table with the ribbon unwinding toward you from both spools, you should see that the spool on the left is unwinding counter clockwise and the spool on the right would unwind clockwise.

To Put on a New Ribbon

Installing the ribbon is a simple task. Hold one spool in each hand and work the ribbon down in front of the paper and behind both guides. Then place the ribbon spools down on the ribbon posts. Turn one of the spools to take up any slack. Now reinstall the ribbon covers so that the notch in the top where the post shows through the cover is turned so the slot matched the top of the post. The covers will not turn if the alignment is not correct. Put the thumb screws back on each cover. You are done!

Burroughs Adding Machine

Class 8 and Class 9

Case Removal Instructions

Removing the case on a Class 8 or 9 machines is fairly easy. There are some cautions to be aware of as follows:

Instructions for case removal

Re-assembly

Generally the removal instructions can be followed in reverse to re-assemble the machine. There are a few areas of special concern as follows:

The machine should be re-assembled and will now operate.

Class 8 and Class 9

Case Removal Instructions

Removing the case on a Class 8 or 9 machines is fairly easy. There are some cautions to be aware of as follows:

- The machine has heavy springs that are under tension when the machine in operated or when the machine is locked in mid cycle. Always be cautious putting fingers between parts if the machine is not fully cycled at home position.

- Electric machines have many open electrical parts and should not be worked on when the machine is plugged in.

- The dash-pot in these machines contains oil. The dash-pot acts as a shock absorber so that the machine handle cannot be pulled fast enough to damage the parts of the secondary section of the machine. The oil sometimes leaks from the dash-pot and may spill out of the machine base if the machine is tipped.

- It is a good practice to take close up photos of the machine parts as they are disassembled. This will allow you a reference point if you are having trouble when reassembling the machine.

- There are many models of these machines with different optional features. Your machine may differ from the instructions. We have tried to include instructions for as many of these optional features as possible in the instructions below.

Instructions for case removal

- If you are working on an electric machine, remove the cord from any electrical receptacle. If hand operated. Pull the handle straight out from the side of the machine.

- If the machine has control keys (to the right of the keyboard) that extend through holes in the case, or extend out over the edge of the case, they should be removed. These types of control keys will always have a screw holding them in place. Remove the screw and lift off the control key.

- Remove the one or two screws holding the upper and lower case parts together in the lower front of the machine. Check the rear of the machine and remove any screws in the lower back of the machine, if present.

- Remove the paper handling mechanism (called the carriage).

- If the machine has a paper roll on the carriage, remove the shaft and associated parts that hold the paper in place.

- There are sometimes two screws holding a small cover in place on the right side of the carriage. Remove these two screws and slide the cover to the right on the platen knob that extends to the right of the carriage. The platen is the rubber roller that the paper wraps around.

- There are three rather large screws that hold the carriage to the top of the machine. These screws have larger heads than most screws. Usually there are two screws on the right side of the carriage and one screw on the left side. The left side screw can be seen from the back of the carriage. Taking a picture of the mechanisms on the right side of the carriage should be done at this point to show haw the parts that connect with the machine itself are placed.

- Lift off the carriage assembly. Notice the parts that extend upward from the machine that were connected to the carriage assembly. These parts advance the ribbon and the paper mechanism during operation.

- Remove the upper case by lifting straight up. Sometimes there are rubber strips around the base of the machine. These help deaden the sound of the machine. They may come off during case removal. These should be re-installed when the machine is re-assembled. At times the rubber is thick enough that the upper case does not lift off easily. If this is the case, slap both sides of the case at the same time while pushing upward on the case. This will usually cause the case to lift off.

- The lower case can also be removed from the machine, but it is normally not necessary. If the lower case is to be removed, turn the machine over (protect the machine and your work surface) and remove the 4 screws holding the lower case in place. These screws are often very hard to break loose and they are frequently sealed with a glue to prevent oil from leaking out. Use a proper sized screw driver, of when possible an open end wrench.

Re-assembly

Generally the removal instructions can be followed in reverse to re-assemble the machine. There are a few areas of special concern as follows:

- Be sure the upper case is all the way down on the lower case before trying to assemble the carriage on to the machine.

- When installing the carriage on the machine, there are usually two control connections with the parts that extend upward from the machine. One is a flat L shaped part of the bottom of the carriage. This part must fit in the saddle part on the machine. This part causes the ribbon mechanism to advance on every machine cycle. The other part is a part with a saddle shaped opening that must fit over a part on the carriage with a roller looking part. This connection drives the paper advance mechanism. Try to align both parts properly (refer to your pictures) and hold the carriage in place with your hand while you cycle the machine (put the handle back in). If the parts are aligned correctly, the machine should cycle and the carriage should stay in place. If the machine locks, or the carriage does not stay in place, the parts are not aligned correctly. Lift off the carriage and try again.

- Once the carriage is in place and screwed down with the three large head screws, try to cycle the machine again. If it locks up, you will need to remove the carriage again.

The machine should be re-assembled and will now operate.

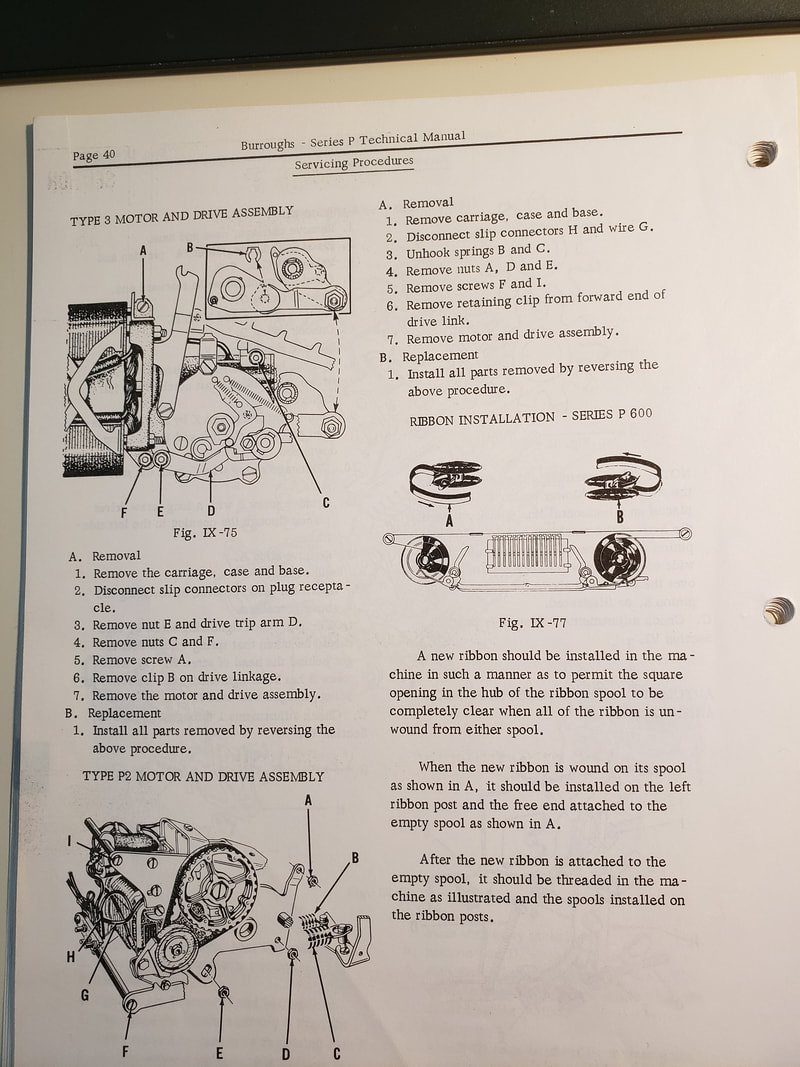

Class 8 & 9 Motor Removal Procedures

There are two types of motors that were used in Class 8 and 9 "portable" adding machines. Type 3 uses a oil filled gearbox at the front of the motor. Type P2 is a belt-drive motor.

I have parts available for Type 3 motors and gear boxes. If you need parts, contact me at questions4Mike@burroughsinfo.com.

The picture below is from a Burroughs technical manual from 1965.

There are two types of motors that were used in Class 8 and 9 "portable" adding machines. Type 3 uses a oil filled gearbox at the front of the motor. Type P2 is a belt-drive motor.

I have parts available for Type 3 motors and gear boxes. If you need parts, contact me at questions4Mike@burroughsinfo.com.

The picture below is from a Burroughs technical manual from 1965.

Class 8, 9, 10 and Series P Operating Tests

Removing the Case on an Early Class 1

Several individuals have reported that they ran into trouble trying to lift off the case on some very early Class 1 machines. It seems there is linkage between the machine and the carriage that appears to only be disconnected by drilling out a pin holding the links together. The links come out of the machine through a hole in the case, making it impossible to lift off the case with the linkage in place.

Thanks to some discovery work done by Jules Richardson, there is a way to remove the linkage without doing any drilling. The following is the description by Jules to what he discovered AFTER drilling out the pin between the links. Also, the pictures Jules has provided help to show how the linkage appears and how it can be disconnected.

Many thanks to Jules for sharing this information.

"The arm which runs through the case to operate the printer actually has a slotted hole on the "inside" end, and so it should be possible to lift it slightly and get it to disengage from the drive mechanism - see the two attached images. I think what has to happen is that the machine's operating handle has to be held in a position where the "drive pin" to which that printer arm connects is immediately below the shaft above it - without that, the angles are such that there's not enough clearance for the arm to lift up and disengage with the pin. It might be that there needs to be some wiggling of the arm, too, because the slotted hole at the inner end is actually oval in shape rather than round.

I know that particular joint had seemed a little loose to me in the past, but I'd put it down to either wear or a design feature (e.g. thinking it perhaps allowed for looser tolerances between the machine and the printer mount without stressing the mechanism)."

Thanks to some discovery work done by Jules Richardson, there is a way to remove the linkage without doing any drilling. The following is the description by Jules to what he discovered AFTER drilling out the pin between the links. Also, the pictures Jules has provided help to show how the linkage appears and how it can be disconnected.

Many thanks to Jules for sharing this information.

"The arm which runs through the case to operate the printer actually has a slotted hole on the "inside" end, and so it should be possible to lift it slightly and get it to disengage from the drive mechanism - see the two attached images. I think what has to happen is that the machine's operating handle has to be held in a position where the "drive pin" to which that printer arm connects is immediately below the shaft above it - without that, the angles are such that there's not enough clearance for the arm to lift up and disengage with the pin. It might be that there needs to be some wiggling of the arm, too, because the slotted hole at the inner end is actually oval in shape rather than round.

I know that particular joint had seemed a little loose to me in the past, but I'd put it down to either wear or a design feature (e.g. thinking it perhaps allowed for looser tolerances between the machine and the printer mount without stressing the mechanism)."

Getting Replacement Burroughs Decals

The Typewriter Decal Shop on ETSI makes custom decals for machines. Go to the "Related Websites" tab to find the link to this great resource.